We're better together

How we collaborate

Stories

What does the carpet of the future look like? Recyclable? Infinitely reusable? Made of one material? Resource-friendly? Two companies have already developed the solution: OBJECT CARPET ∞ NIAGA® – a cooperation that literally could go on forever. An investment in the future, also at the production site in Krefeld.

Lars Engelke (Managing Director, Product Development OBJECT CARPET) and Chris Reutelingsperger (Founder, Niaga®)

Photo: OBJECT CARPET

The objective was worded clearly and unambiguously: “together we want to develop the highest-quality, healthiest, most sustainable and first completely recyclable carpet in the world,” said Lars Engelke, Managing Director of Product Development.

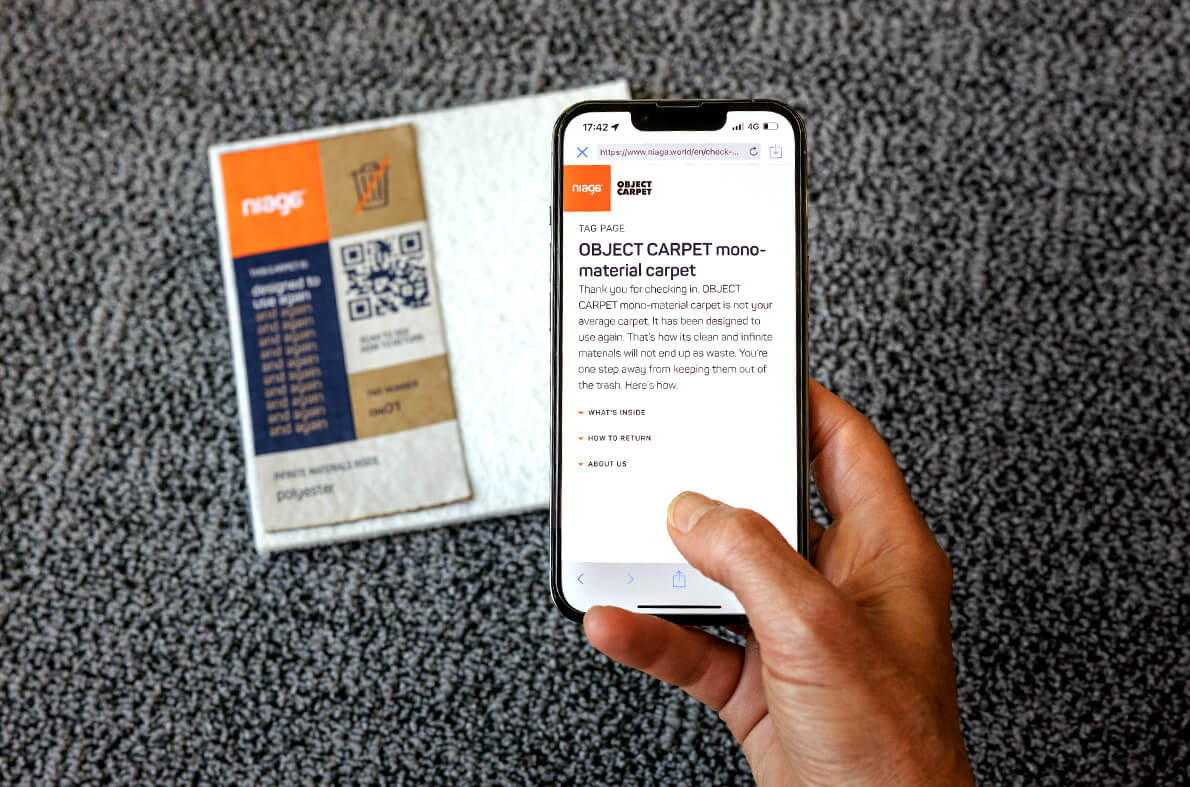

The accompanying vision DESIGNED FOR ENDLESS LIFE – FOREVER YOUNG aims to achieve a perpetual product life in endless cycles – perfectly aligned with the concept of a circular economy. But what exactly do circularity and recycling entail? A circular economy describes an interaction of various decisions, processes and the position, seriousness and conviction of individuals and companies. Product design forms the basis for sustainable, healthy and circular products in terms of technical structure and material composition. Likewise, honesty and transparency with regard to materials, ingredients, production processes and relevant product-specific data are imperative for a circular economy. “Kill waste. Design for reuse,” is the concept called by Chris Reutelingsperger, founder of Niaga®. The recyclability and recycling process requires experts and specialists for the materials, logistics and reprocessing as well as the interest and cooperation of the customers and all partners. In the future, the return process for the carpets will be facilitated by the so-called Niaga® tag – this label attached to the product indicates that the product should not be discarded and also provides additional information, such as the material composition and return procedure. “Because the return of the products is central to the circular economy.

“Developing a recyclable, resource-friendly and clean carpet has been and still remains one of the greatest challenges in this company’s history. It is therefore all the more exciting that in Niaga® (“again” backwards), we were able to find a partner that can contribute their technical and material expertise to this development,” said Lars Engelke. The company, which is part of the Covestro Group, has made it its mission to change products and industries in a sustainable way – “we design to use again” or “let’s design our waste, completely,” are statements that Niaga® lives by and implements, making it one of the movers and shakers in the circular economy.

When two such companies come together – OBJECT CARPET ∞ NIAGA® –, something great is bound to emerge. And yes, the current development level shows that a 100% recyclable carpet is not just wishful thinking, but reality.

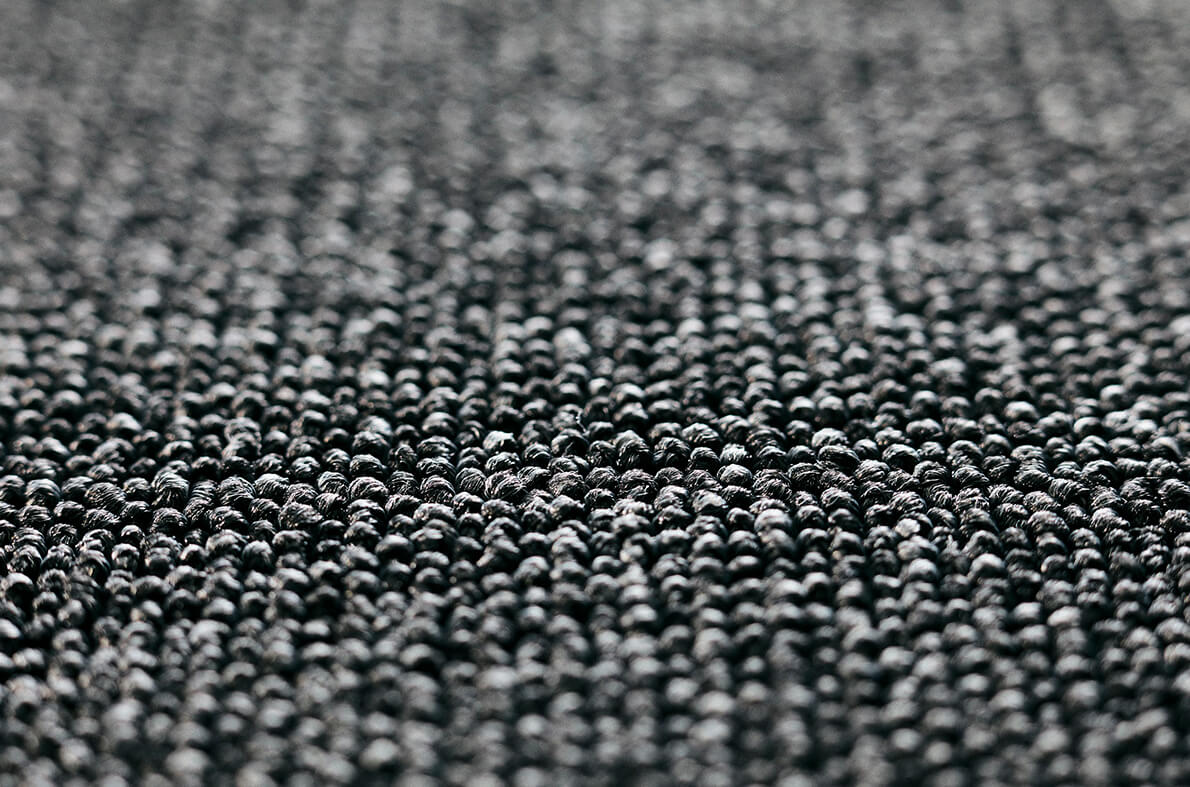

The result: a mono-material carpet fully made of polyester and completely recyclable, without waste and litter. Thanks to its qualities, this product outshines any previous textile floor coverings. Suitable for the commercial property sector, for offices and hotels, easy to install, easy to clean, and fully recyclable at the end each use cycle. A carpet with lifelong value. Because material is seen as a resource with value – where age and condition become irrelevant. But why choose polyester? Polyester is a family of materials that can easily be recycled without impacting the quality. This makes polyester the most frequently recycled synthetic material in the world, as it retains its original characteristics and can therefore be used throughout many lifecycles with the same high-quality application.

For comparison: a traditional textile floor covering is a mix of many different materials with various functions, such as yarn for the top layer, for example. Then there are also supporting materials, bonding elements, such as latex or fillers for the inverse backing that ensure stability and weight. These materials are bond together in an irreversible way. In addition, many of these fabrics and materials are used in carpeting not because of their functions, but rather due to their availability or low price. Here, the sustainability and recyclability of these materials often play a secondary role, if any.

The cooperation between OBJECT CARPET ∞ NIAGA® also goes hand in hand with the future viability and significance of the Krefeld production site. This state-of-the-art and innovative production facility for manufacturing polyester-based carpets forms the central building block in a comprehensive carpet production – completely in line with MADE IN GERMANY.

The newly completed transparent manufacturing offers customers and partners the opportunity to experience the creation and production process both in real time and in color in Krefeld. At this site, visitors can use all their senses – seeing, smelling, touching – to learn how a production runs without waste, how and what is recycled, how few resources this takes and what the finished product resembles. What is particularly interesting here is the innovative coating facility, which uses a process that requires no gas or water and is 90% more efficient than conventional production methods.

Developing a holistic concept from many approaches, ideas and solutions all the way to implementing a circular economy requires resolve, interest and enthusiasm. For this reason, our motto “Join the future” calls on customers, partners, associations, networks and recycling experts to participate and get involved in the circular carpet project. Because recycling can only happen if everyone has recognised the principle of valuable raw materials and helps integrate products back into the manufacturing process. This is the only way to establish and implement a comprehensive recycling process, from the product, return and recirculation all the way to recycling, raw materials and resources – no time to waste.

The first circular mono-material carpet will be launched in September this year.

Video link to the event: https://www.youtube.com/watch?v=ldCfLnXrvn8

Carpet backing with Niaga® tag Photo: OBJECT CARPET

Mono-material carpet made of polyester Photo: OBJECT CARPET

Event panel participants: Lars Engelke / OBJECT CARPET, Caterina Micucci / UNStudio, Chris Reutelinsperger / NIAGA, Tanja Kliewe-Meyer / Like a Bird, Björn Polzin / sop architekten, moderator Louisa Schneider / SWR (l.t.r.)

Photo: Simon Wegener

Innovative coating facility, which uses a process that requires no gas or water and is 90% more efficient than conventional production methods.

Photo: Simon Wegener

Transparency: QR code informs about circularity and material details

Photo: Simon Wegener

Since 1972, OBJECT CARPET has stood for quality, design and innovation in the commercial property sector. A sense of aesthetics and color, in combination with advanced production techniques, results in high-grade and extraordinary designs in the form of broadloom, carpet tiles and custom-cut carpets (RUGX). With over 1,000 styles and colors as well as individually-customised products, the OBJECT CARPET collection offers a unique diversity for modern interior design, manufactured from high-quality raw materials. All OBJECT CARPET styles are also free from harmful emissions and are bitumen-free, latex-free, and PVC-free. They bear the German Federal Environmental Agency’s Blue Angel ecolabel. Producing carpets from recycled materials and the aspiration to give these a second lifecycle is a matter of principle for OBJECT CARPET. To reduce its own ecological footprint, OBJECT CARPET is consistently working on sustainable solutions and investing in new technologies. So it was no surprise that the company was selected to provide the “VIP carpet” for the German Sustainability Award ceremony. OBJECT CARPET products received the evidence-based recommendation from the TÜV (German Technical Inspection Association) for safe use by allergy sufferers and reduce dust content and particulate matter. Partners and customers around the world, such as Porsche, Daimler, Google and Adidas appreciate this, as do initiatives like “Healthy Seas”.

Numerous design and business awards, such as the prestigious Good Design and Red Dot Awards, have demonstrated OBJECT CARPET’s outstanding design competence and corporate achievements. For example, OBJECT CARPET was chosen as one of the “top 50 German luxury brands” by Ernst & Young and voted one of the “brands of the century” by Langenscheidt.

With innovative production techniques and sustainable manufacturing methods, OBJECT CARPET breaks new ground and turns visions into reality. Experience OBJECT CARPET’s world of color and materials in any one of the company's showrooms in Germany, Austria, and Switzerland.

Contact::

Yvonne Schumacher

Tel.: +49 711 3402 191

E-Mail: yvonne.schumacher@object-carpet.com

Contact for editorial offices:

GeSK | Ziegelstr. 29 | 10117 Berlin

Tel.: +49 (0) 30/217 50 460

Fax: +49 (0) 30/217 50 461

E-Mail: pr@gesk.berlin

Web: www.gesk.berlin

At Niaga®, we are future-proofing everyday products by making sure materials don't have to end up as waste. Ever. Together with our partners, we design out waste, completely. We design to use again. So far, we have developed mattresses, carpet, and furniture panels. They are healthier and fully recyclable, without compromising on performance. By scanning the Niaga® tag on our partners’ products, you’ll see exactly what they are made of and how they can be returned. More product redesigns are underway. Niaga® is part of Covestro.

Contact:

Sascha Bloemhoff

Tel.: +31 6 2001 5064

E-Mail: sascha.bloemhoff@covestro.com